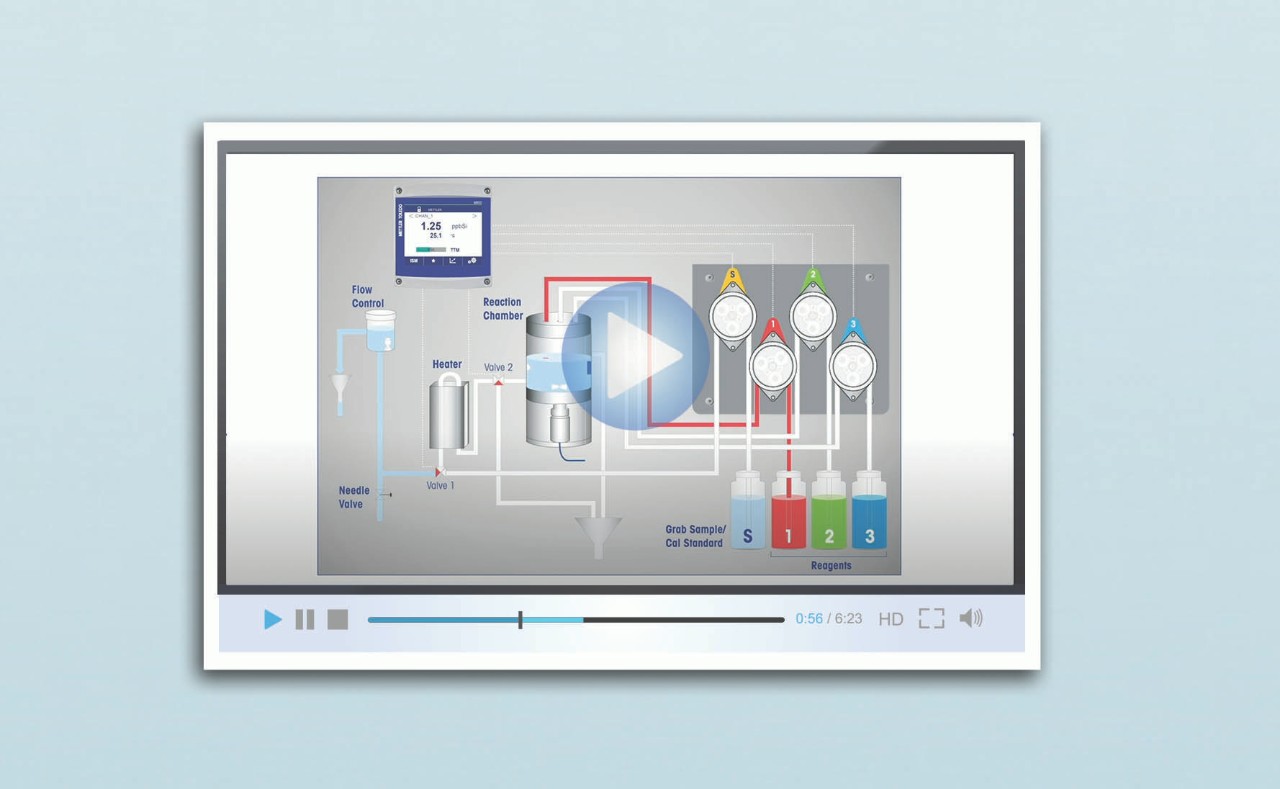

How the Silica and Phosphate Analyzer Works

The silica and phosphate analyzer 2850Si supports the combined online measurement capabilities of a silica and phosphate analyzer. This saves valuable time and maintenance cost with more functionality in one single instrument. The video explains how the silicomolybdate complex produces a color change that allows the silica and phosphate analyzer to measure concentrations of silica and phosphate.